Working principle

Wood Chipper Crusher

Chipping and crushing all-in-one machine series is a composite device with both chipping and crushing functions. It can crush wood chips at the same time in the process of cutting wood chips to make wood chip materials smaller. This series of equipment is mainly suitable for processing pine, miscellaneous wood, poplar and other materials, can also process non-wood fiber materials such as veneer, corn stalk, straw, sorghum stalk, reed,etc.

Product display

Aite Pellet machine is mainly suitable for the production of all kinds of different raw material pellets. It is mainly composed of drive system, feeding system, pelletizing system, etc.

Wood crusher integrates cutting and crushing. Blades cutting and high speed air impacting works together to make it a good crushing machine. During blade cutting, rotator creates high speed air and spins with blade cutting direction. Raw materials speed up in the air and impact repeatedly to crushed them completely. Wood crusher mainly consists of cutting device,crushing equipment and draught fan. Small body and good flexibility.

Customer equipment site

Applicable materials

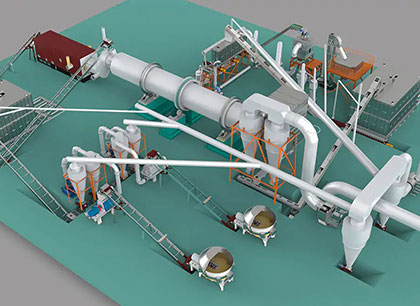

Biomass fuel production line

Our biomass fuel production line integrates core technologies for pretreatment, molding, and pelletizing. We offer customized solutions, including "pellet fuel line" and "biomass pellet production line," tailored to customer needs, achieving fully automated, closed-loop production from raw materials to finished product.

- Intelligent Pretreatment System: A pre-installed wood chipper rapidly processes large materials, improving pretreatment efficiency by over 50%.

- High-Efficiency Molding Unit: Utilizing an imported ring die pelletizer with a compression ratio of 1:8-1:12, we produce biomass pellets with a density of 1.1-1.4 g/cm³, a stable calorific value of 15-18 MJ/kg, a molding rate exceeding 98%, and an output of 1-5 tons per unit, meeting production needs of varying scales.

- Fully Automatic Control System: Equipped with a PLC intelligent control cabinet, it monitors parameters such as temperature, pressure, and output in real time, enabling one-button start and stop, reducing manual operations, improving production stability by 25%, and reducing labor costs by 40%.

The biomass fuel produced by our production lines is widely used in four major sectors: residential heating, industrial heating, biomass power generation, and transportation fuel.

- Residential: Biomass pellets replace coal for home heating and barbecues, offering smokeless, odorless, clean, and convenient use.

- Industrial: They provide heating fuel to ceramics, building materials, and food processing companies, reducing production costs.

- Power Generation: They provide stable fuel for biomass power plants, enjoying benchmark electricity price subsidies.

- Transportation: After modification, biomass liquid fuel can be mixed with gasoline and diesel, contributing to the transportation energy transition.

Welcome contact us for a free proposal.

Pellet Production LIne

Advantage

Parameters

| Model | AIT-400 | AIT-600 | AIT-800 | AIT-1000 |

Cutter Diameter (MM) | 400 | 600 | 800 | 1000 |

| Cutting Tip Amount | 4 | 4 | 6 | 6 |

| Cutting Tip Length (MM) | 95 | 180 | 260 | 300 |

| Power (KW) | 7.5 | 15 | 30 | 45 |

| Capacity (KG/H) | 300-500 | 600-700 | 800-1200 | 1800-2000 |

| Dimension (M) | 1.1*0.7*0.95 | 1.5*0.8*1.2 | 2.1*1.1*1.4 | 2.1*1.2*1.6 |

| Weight (KG) | 450 | 700 | 1100 | 1350 |

Whatsapp:+8617513178882

Whatsapp:+8617513178882